Unbeatable value with key features as standard

- Strong frame design to minimise deflection during cutting

- User-Friendly Touchscreen controller avoiding operator misuse.

- Automatic blade gap setting, cut length, backgauge stroke and counter

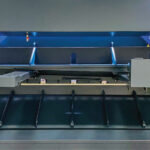

- Ball transfers on table for smooth handling of the sheets.

- Enlarged backgauge stroke to 1000 mm

- Side squaring arm with ruler lengths up to 1500mm

- Front support arms 1000 mm with slot and flip-stops

- Flip-up finger guard of 1000 mm at cutting area.

- Sheet slider at rear for easy falling of sheets

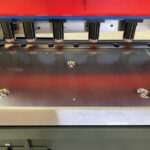

- Rubber pads underneath holddown pistons to avoid scratching of materials

- Led illumination at cutting area

- Swivelling pendant arm for the controller moving with the operator.

Pneumatic sheet support with 1 step with extended arms reaching to the blades

2 step acting pneumatic sheet support for smoother handling of the cut piece

Holddowns with safety housing and rubber pads

Flip-up finger guard

Front side collection box for small cuts

Automatic lubrication system

BTS TECHNICAL DATA

| 2006 | 2010 | 2013 | 2506 | 2510 | 2513 | 3006 | 3010 | 3013 | 3016 | 4006 | 4013 | |

| Capacity (length x cutting capacity ) | 2060 | 2060 | 2060 | 2560 | 2560 | 2560 | 3060 | 3060 | 3060 | 3060 | 4060 | 4060 |

| Cutting performance for material tensile strength 400 N/mm² | 6 | 10 | 13 | 6 | 10 | 13 | 6 | 10 | 13 | 16 | 6 | 13 |

| Cutting performance for material tensile strength 600 N/mm² | 4 | 6 | 8 | 4 | 6 | 8 | 4 | 6 | 8 | 10 | 4 | 8 |

| Rear stop speed | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 |

| Cutting angle (min/max) | 1,5° | 1,5° | 1,8° | 1,5° | 1,5° | 1,8° | 1,5° | 1,5° | 1,8° | 2° | 1,2° | 1,8° |

| Max. strokes for full cutting length (min/max) | 24 | 14 | 14 | 22 | 14 | 14 | 20 | 12 | 12 | 10 | 12 | 8 |

| Number of hold-down units | 12 | 12 | 12 | 15 | 14 | 14 | 17 | 16 | 16 | 16 | 21 | 21 |

| Oil tank capacity | 180 | 250 | 320 | 180 | 260 | 320 | 180 | 260 | 320 | 440 | 180 | 320 |

| Dimensions and weights | ||||||||||||

| Table length | 2320 | 2410 | 2540 | 2820 | 2910 | 3010 | 3320 | 3410 | 3510 | 3580 | 4330 | 4510 |

| Table depth | 485 | 590 | 590 | 485 | 590 | 590 | 485 | 590 | 590 | 605 | 485 | 590 |

| Table height | 800 | 900 | 900 | 900 | 800 | 900 | 900 | 900 | 900 | 900 | 850 | 900 |

| Machine body depth | 1535 | 1985 | 1985 | 1535 | 1985 | 1985 | 1535 | 1985 | 1985 | 220 | 1635 | 1985 |

| Length approx. | 2900 | 3030 | 3140 | 3530 | 3520 | 3640 | 3900 | 4030 | 4140 | 4220 | 4950 | 5140 |

| Width/depth approx.(with Back Fence and Front arms) | 3275 | 3300 | 3300 | 3275 | 3300 | 3300 | 3275 | 3300 | 3300 | 3480 | 3120 | 3300 |

| Height approx. | 1900 | 2130 | 2175 | 1900 | 2130 | 2175 | 1900 | 2130 | 2175 | 2220 | 1900 | 2325 |

| Weight approx. | 5100 | 7300 | 12000 | 5450 | 9300 | 13000 | 6550 | 10300 | 14200 | 16500 | 9510 | 17100 |

| Electric Data | ||||||||||||

| Drive motor output | 11 | 22 | 30 | 11 | 22 | 30 | 11 | 22 | 30 | 37 | 11 | 30 |

BTR Serie RAKE ANGLE Shears

Angle Rake (Guillotine) Shears cut with a straight vertical motion and allow adjustable cutting angles, offering higher accuracy, efficiency, and versatility for different material thicknesses

Standards

- Motor-driven back gauge with two speeds A.C. motor and recirculation ball screws and linear rod guides.

- Electronic programmer with microprocessors Touchscreen Cybelec Cybtouch 8G for automatic control of:

- cutting angle

- blade gap

- Hold down pressure

- cutting length

- programming of back gauge

- stroke counter

- Motorised blade distance adjustment with dimensional mechanical control.

- Spherical balls in table for easy sheet movement (Transfer balls)

- Stainless steel table tops

- Sheet slider at rear

- Side squaring arm 1500mm

- Standard extension arms 1000mm

- Cutting light & wire

- Induction hardened and ground Blades for mixed cutting

- Control foot pedal

- Instruction and maintenance manual

- Machine according to standard 2006/42/CE and CE certificate

| Technical Data | BTR 3006 | BTR 3010 | BTR 3013 | BTR 3016 | BTR 3020 |

| Capacity (length x cutting capacity ) | 3060×6 | 3060×10 | 3060×13 | 3060×16 | 3060×20 |

| Cutting performance for material tensile strength 400 N/mm² | 6 | 10 | 13 | 16 | 20 |

| Cutting performance for material tensile strength 600 N/mm² | 4 | 8 | 10 | 13 | 16 |

| Rear stop speed | 150 | 150 | 150 | 150 | 150 |

| Cutting angle (min/max) | 0,5 °- 2° | 1 °- 2,5° | 1 °- 2,5° | 1 °- 2,5° | 1 °- 2,5° |

| Max. strokes for full cutting length (min/max) | 20-25 | 15-24 | 14-20 | 13-24 | 10_22 |

| Number of hold-down units | 18 | 13 | 13 | 12 | 12 |

| Oil tank capacity | 310 | 280 | 280 | 580 | 650 |

| Dimensions and weights | |||||

| Table length | 3580 | 3600 | 3640 | 3680 | 3700 |

| Table depth | 540 | 670 | 700 | 720 | 700 |

| Table height | 860 | 900 | 900 | 900 | 950 |

| Machine body depth | 1710 | 2200 | 2300 | 2850 | 2600 |

| Length approx. | 3900 | 4200 | 4200 | 4180 | 3800 |

| Width/depth approx.(with Back Fence and Front arms) | 3900 | 4150 | 4250 | 4800 | 4550 |

| Height approx. | 2100 | 2300 | 2350 | 2800 | 2800 |

| Weight approx. | 10000 | 13550 | 16200 | 19550 | 27050 |

| Electric Data | |||||

| Drive motor output | 11 | 22 | 30 | 37 | 45 |

| Backgauge Stroke | 1000 | 1000 | 1000 | 1000 | 1000 |

Products

BSA - CNC Pressbrake

BSAH - HYBRID CNC Pressbrake

BTS - Swing Beam + BTR Angle Rake Hydraulic Guillotine Shears

PFO - Farina Pressbrakes

CFO - Farina Shears

RMA - Mechanical Guillotine Shears

RMS - Mechanical Guillotine Shears

RMT - Mechanical Guillotine Shears

SVK - CNC Folders

SPECIAL - Automation Lines